Everyone can agree that there is no shortage of handbag styles to choose from in the modern world. Whether you're looking for something that screams the latest runway trends or a quieter style with the potential for decades of longevity, there are literally hundreds of potentially “perfect” designer bags out there to suit your tastes.

What makes this virtual cornucopia of handbags all the more impressive is the sheer amount of energy that goes into the design and manufacturing of each and every one. While there is little reason for most of us to stop and think about the process of producing a handbag, appreciating what goes into the design and manufacturing process will certainly serve to make you appreciate your next addition to your collection all the more. Here, we break the lifecycle of a handbag down for you.

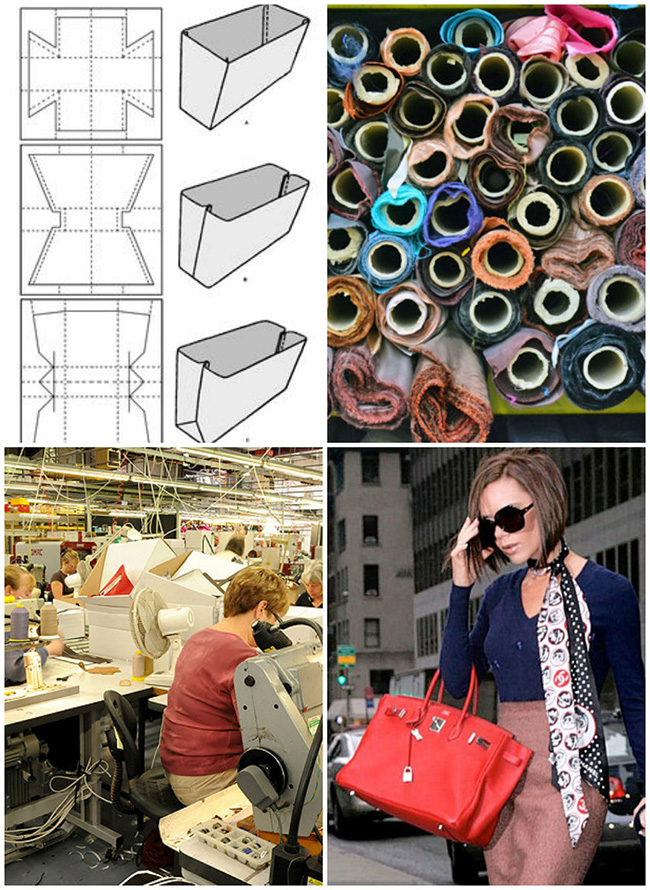

Step 1: Conceptualization

A designer's inspiration can come from absolutely everywhere; once the seed is planted, the designer creates a sketch of the potential design.

Step 2: Material Selection

The design team will select the perfect material for the handbag design. Whether it be leather, cloth, or vinyl, elements like color, texture, and the structure of the bag will dictate which material will best align with the designer's vision. Hardware is also decided in this step, as well as any branded materials such as turn-locks and logo plates.

Step 3: Cutting the Pattern

Once the design concept and materials have been decided, it is time to cut a functional pattern for the bag. This is a critical step, as the functionality of the bag must meld perfectly with the design, or the design house risks a large expenditure of cash and effort on a design that simply doesn't work.

Step 4: Creating a Prototype

At this stage, the design team will cut and assemble a prototype bag using their pattern and selected materials. It is during this stage that they can work out any design issues and change materials as needed.

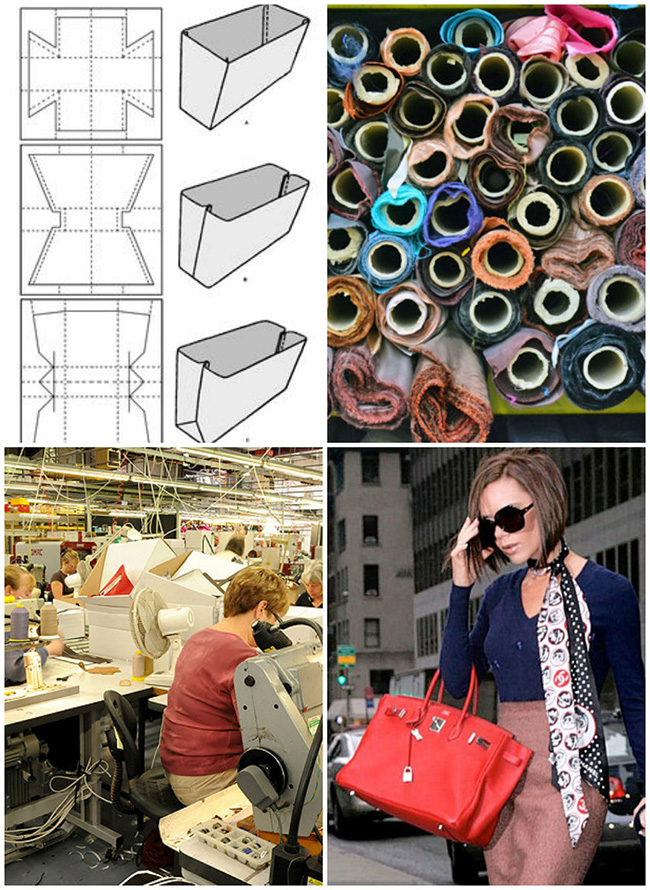

Step 5: Off to the Factory

Once the prototype has been tweaked, the pattern is sent to the factory for production. During this stage, the quality control process is important to ensure a consistent quality of product that is in keeping with the brand's identity.

Step 6: Off to Market

This is where you come in. Once a bag passes the quality control check, it is packaged and sent off to retailers for handbag enthusiasts to browse and add to their collections.